Description

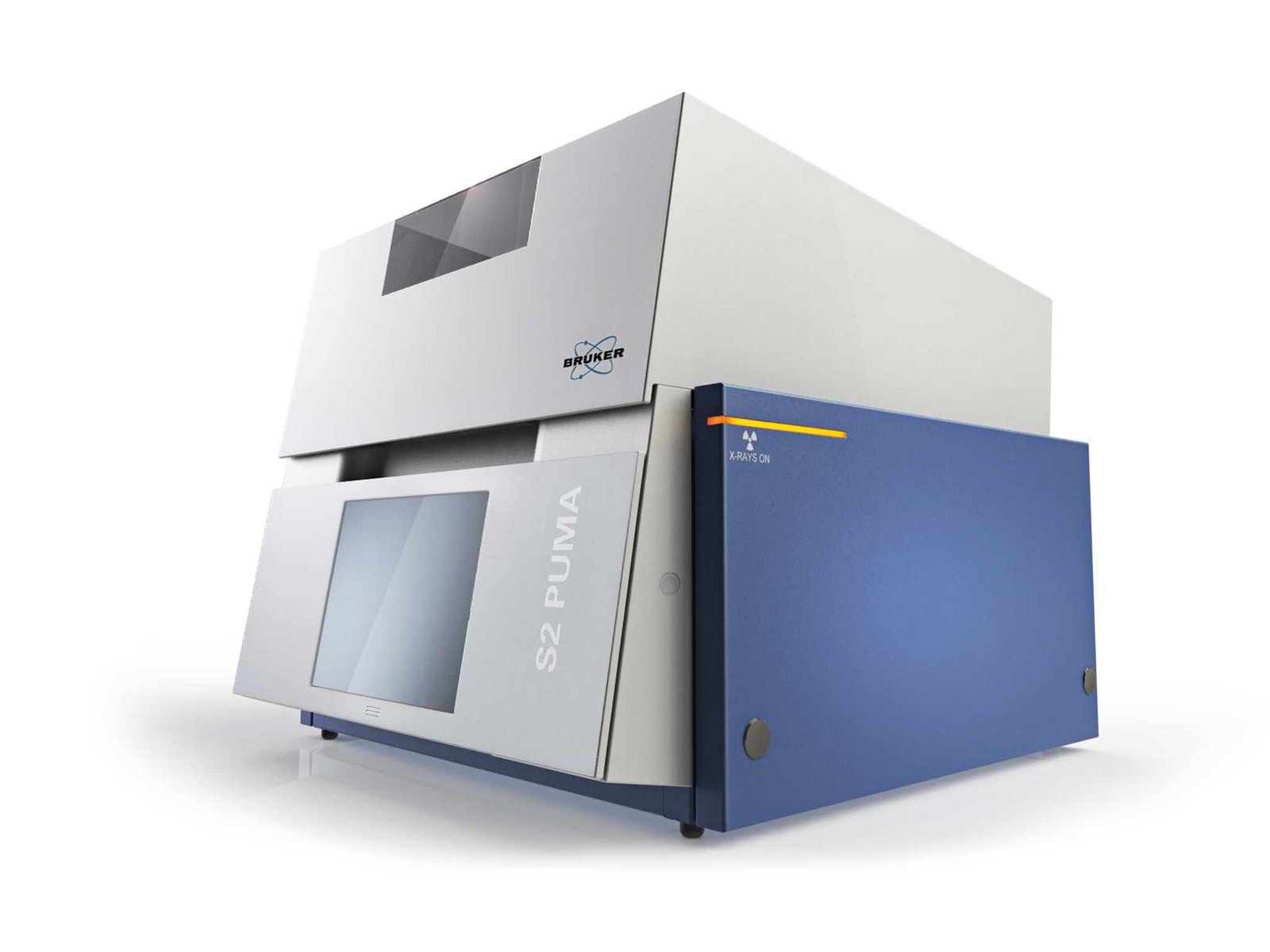

The Bruker S2 PUMA Series 2 represents a series of benchtop X-ray fluorescence (XRF) spectrometers designed for various analytical tasks. XRF is a non-destructive analytical technique used to determine the elemental composition of materials.

The Bruker S2 PUMA Series 2 is designed for fast and precise elemental analysis across various sample types. Its compact benchtop design and advanced XRF technology make it a popular choice for laboratories and industries looking for accurate and rapid results.

Key Features:

- High Precision & Sensitivity: Bruker’s technology ensures that even trace elements are detected accurately. This is crucial for applications where precise quantification of elements is required.

- Broad Elemental Range: The device can typically detect and quantify elements ranging from light elements like sodium (Na) to heavy elements like uranium (U).

- Versatility: With various sample holders and rotatable trays, the S2 PUMA Series 2 can handle solids, liquids, powders, and thin films.

- High Throughput: Designed with industrial applications in mind, Series 2 offers features that allow for high sample throughput, facilitating continuous and batch analyses.

- TouchScreen Interface: A modern interface provides intuitive software controls, streamlining the analysis process.

- Safety and Protection: The benchtop design ensures that the X-ray source is shielded, prioritizing user safety.

Applications:

- Quality Control: Industries like cement, minerals, and polymers often employ the S2 PUMA Series 2 for QC purposes, ensuring that products meet desired elemental specifications.

- Environmental Analysis: Laboratories focused on environmental monitoring can analyze samples like soil, sediments, and air filters to detect contaminants.

- Research & Academia: The high precision of the S2 PUMA Series 2 makes it suitable for academic research where detailed and accurate elemental profiling is required.

- Metallurgy & Mining: Assessing the composition of ores, alloys, and metals is streamlined with the S2 PUMA, guiding extraction and refining processes.

- Petrochemicals: The spectrometer can also analyze the elemental composition of oils and fuels, aiding in quality checks and exploration decisions.

The Bruker S2 PUMA Series 2 combines compact design with advanced XRF capabilities, offering labs and industries a powerful tool for diverse analytical tasks. Its precision, versatility, and speed make it an invaluable asset for elemental analysis.

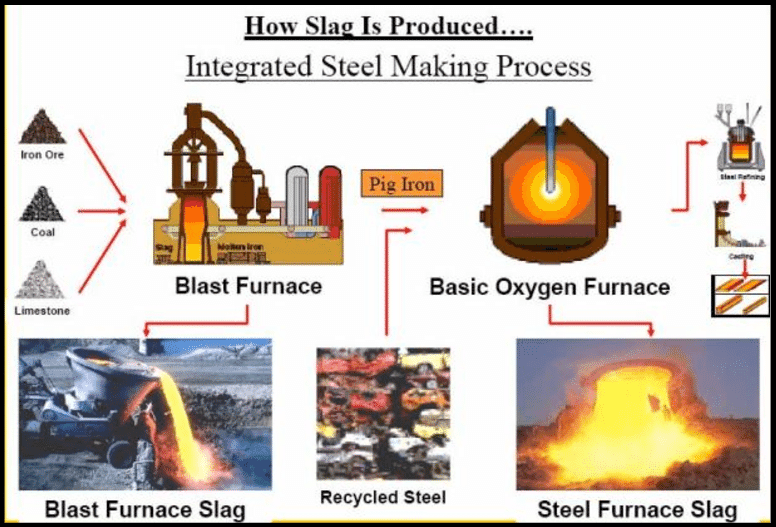

Precisely Access the Slag Furnace Condition with the S2 PUMA Series 2!

For Steelmakers seeking to manufacture steel more profitably, it is essential to adopt technologies and processes that allow for monitoring and sampling slag more efficiently and cost effectively. Because of the highly integral role of slag in steel manufacturing, it is critical that these prospective technologies and processes are at a minimum: reliable, repeatable, accurate, and that the instrument functions properly in difficult manufacturing environments.

Slag is an important agent in high temperature metallurgical processes and is tuned to an equilibrium condition for maximum action on the metal purity, least attack on the refractory lining, and optimal physical properties.

Dosage of slag enhancing additives such as lime, dolomite, or other additives is performed based on the chemical composition of the slag determines the subsequent by-product sale, creating an additional revenue generating product.

The Perfect Fit – S2 PUMA Slag Analyzer

The S2 PUMA is a ruggedized benchtop energy dispersive X-ray analyzer developed for tight process control in industrial applications.

It is the optimal tool to measure the composition of slags on the shop floor, enabling plant operators to make critical decision within 10 minutes after sampling (including sample preparation) and, thus, in time to ensure optimum dosing of additives (e.g. lime). State-of-the-art X-ray technology enables the S2 PUMA to quickly achieve the analytical accuracy and precision required at the steel plant, helping to reduce costs and improve production efficiency

Specification | Benefit | |

Element Range | Sodium to americium (Na – Am) Carbon to americium (C – Am) with light element detector | Covers most of the periodic table of elements |

Concentration Range | From ppm to 100 % | Measures major and trace elements in one sample |

X-ray Tube | Pd or Ag anode; 50 W, max. 2 mA, max. 50 kV (30 kV available) | High power combined with direct excitation and closely-couples beam optics for optimal analytical performance |

Primary Beam Filters | 10-position automatic filter changer | Optimized excitation for enhanced peak-to-background ratio. Protects the X-ray tube. |

Detector | HighSense™ (Na – Am) HighSense™ XP (C – Am) | Peltier cooled Silicon Drift Detector (no need for liquid nitrogen) protected DustShield™ Super-high count rates and excellent energy resolution. |

Collimator Masks* | 1, 3, 8, 12, 18, 23 and 28 mm (34 mm without mask) | For small spot analysis |

Sample Observation* | Integrated HD video camera | For exact sample positioning and documenting the measurement position on a sample |

Atmosphere Modes | Air mode | For heavier elements in all sample types |

Vacuum mode* | Best light element performance for stable samples and lowest cost of operation | |

Helium mode*: | For best light element analysis in volatile liquids such as fuels | |

Helium mode with reduced pressure* | For best light element performance with non-volatile liquid and loose powder samples and lowest helium consumption | |

Nitrogen mode* | Cost saving analysis of liquid samples | |

TouchControl™* | Integrated 12.1” TFT touchscreen, adjustable, languages: English, German, French, Spanish, Portuguese, Italian, Russian, Chinese and Japanese (others on request) | Easy and Failsafe operation (only minimal training required) |

Sample Types | Loose powders, granules, solids, pressed pellets, fused beads, and liquids | Analyze all sample types |

Sample Rotation* | Spins all sample types and sizes | For better measurement statistics with inhomogeneous samples |

Connectivity | Built-in Ethernet port RJ45, 3x USB ports for mouse, keyboard, printer | Easy to connect to your network |

Power Requirements | 100-240 V, 50/60 Hz, max. power consumption 600 VA | Standard wall plug |

Quality & Safety | DIN EN ISO 9001:2015, DIN EN ISO 14001:2015, 2006/42/EC (CE-certified Machinery directive), 2014/35/EC (Electrical equipment), 2014/30/EC (Electromagnetic Compatibility), German Type Approval and Vollschutz according to BfS RoV, fully radiation-protected system; radiation <1 μSv/h (H*), Compliant to ICRP, IAEA, EURATOM | |

| *optional packages | ||

Reviews

There are no reviews yet.